Starting the New Season!

Patterson Farms is gearing up for maple season as the taps start going in and the sap begins to flow. Lines are being checked, equipment is getting ready, and the farm is coming back to life with the promise of another sweet season ahead! 🍁

Potter-Tioga Maple Producers Association

Hard working and award winning, the maple producers of Potter and Tioga counties in North-Central Pennsylvania are proud to share their passion and sweet products with each and every customer they serve.

Video

Welcome to another episode of Explore The Possibilities with Visit Potter-Tioga

Terri and Terry Patterson, 4th generation maple producers at Patterson Farms, give some insight on their family business, the growth it has seen over the years, the amazing products they have available, and the sights you get to see when visiting.

Visit Potter-TiogaFourth-generation PA. maple farm reflects on their legacy

This fourth-generation farm shows no signs of slowing down because there's one factor they understand to be crucial to their business: family.

WETM 18 News Article

Beef for Sale!

Patterson Farms is offering 100% grass fed beef - USDA inspected - in the store. At this time, we have hamburger and roasts - $6.00/lb. If you're interested in more beef, we can do that too! Beef is available by quarter, half, and whole cuts. Call or contact us today to discuss ordering your next freezer beef!

Bourbon Infused Maple is here!

Our Bourbon Infused Maple Syrup is currently available! It is aged in a whiskey barrel, which gives it a delicious bourbon flavor. It comes amber rich in our 200ml flask, and is $10.50 online, or, $9.50 at the sugarhouse! Taste testing is available at the sugarhouse. Limited supplies available!

Pennsylvania Maple

Did you know that Pennsylvania is a leading producer of maple syrup? When you buy local maple from your neighborhood maple producer, you’re investing in your community. From savory glazes to decadent desserts, this sweet treat unlocks a world of culinary possibilities!

Video

Check out our Featured Products

Our Sugar House Tour!

Faces Behind the Bucket

Maple Storage, Nutrition, and Allergen Information

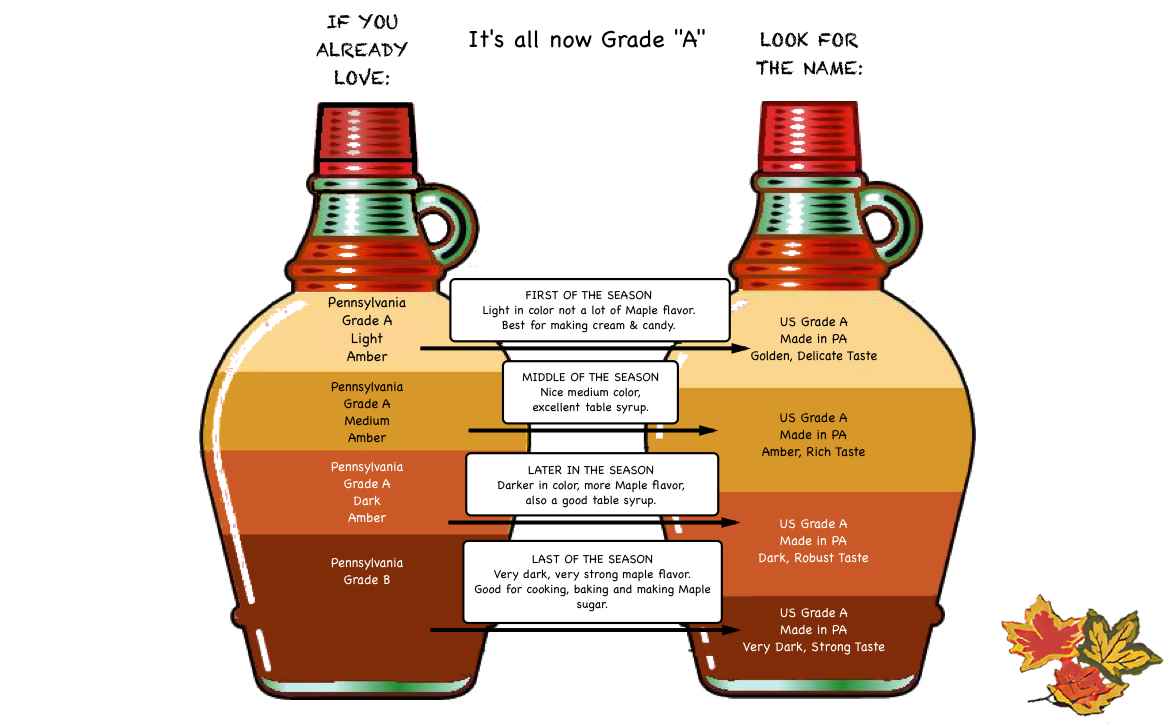

Syrup Grades

Prior to 2015, each state had a maple syrup grading system of its own. In 2015, the USDA went through the process and developed a uniform grading system. This is now the standard to go by. Please use this chart for conversion from the old PA system to the new US system.

Gallery

Contact Us

M-F: 10AM to 5PM

Sat: 9AM to 3PM

119 Patterson Road

Westfield, PA 16950

(814)-628-3751

Google Maps DirectionsOur Goal

We take pride in producing the finest quality maple syrup, cream, candy, sugar, gift baskets, and much more, all for those who enjoy the pure taste of nature's premium sweetness.

Know First

Get email offers & the latest news from Patterson Farms!